Materials Engineering

DEVELOPMENT OF INNOVATIVE AND SUSTAINABLE MATERIALS

The development of innovative and sustainable materials is a crucial success factor for companies, especially in a context of increasing technical and commercial competition. Our researchers, always very attentive to market trends, develop the most appropriate formulations according to the objectives of the final application and processing technologies (injection molding, extrusion, blow molding) through melt blending (compounding) and reactor polymerization technologies.

-

Biopolymers

-

Plastic end-of-life

-

3D Printing

- Composites

- Conductive polymers

Biopolymer

The use of biopolymers for the production of everyday objects is an opportunity to build a more sustainable future. In this area, Proplast researchers develop formulations with high environmental sustainability characteristics as an alternative to fossil-derived thermoplastic polymers

- building a sustainable future

- alternative to thermoplastic polymers

- formulations with high environmental sustainability

Plastic end-of-life valorization

We also promote environmentally sustainable solutions for the plastics industry through business support for other specific activities

- Post-consumer plastics certification as a second raw material according to UNI 10667 standards

- Exploratory testing on use of end-of-life plastics for high value-added products

- Validation of tire powder for uses as an additive to thermoplastic compounds

- Laboratory testing for quality control of end-of-life plastics

Composites

Lightness and strength are the main properties of fiber-reinforced composites.The opportunity to achieve metal-like mechanical performance, having a significant weight reduction, is a feature of considerable interest to various industries. New sectors of the manufacturing industry, as well as the world of transportation, are looking closely at the great advantages of these materials. In this spread, thermoplastic composites play an important role in the manufacture of innovative and high-performance products. Proplast is able to support companies in choosing composites suitable for structural uses for the most challenging contexts

- resistance

- weight reduction

- Metal-like mechanical performance

- stainlessness

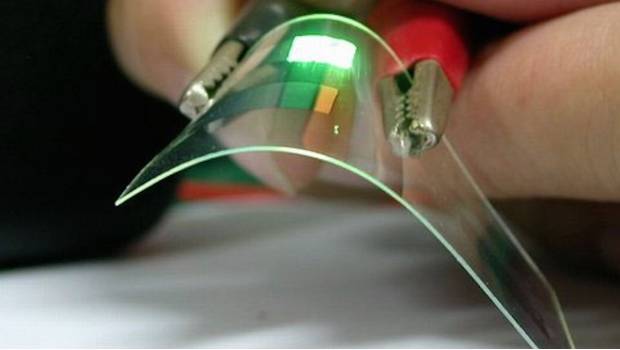

Conductive polymers

Plastic is an insulator, both thermally and electrically.This effectively prevents its use in many applications, where instead its processing characteristics and mechanical performance would make it desirable. For this reason, through the addition in compounds of suitable fillers, the need arises to develop thermoplastics with application-specific conductivity values

- caricati composti

- formulation of thermoplastic conductive materials

- Consulting and development of ad hoc formulations

- applied process engineering consulting

Formulation of materials for 3D printing

Consulting and development of materials for a wide variety of applications

Life Cycle Analysis (LCA)

Life Cycle Analysis (LCA) is a method for quantifying the environmental impacts associated with all the stages of the life cycle of a given product/process. It takes into account the stages from extraction of raw materials to end of life disposal, considering also the production process, transports and the use phase. An LCA study of a product/process can be used for various purposes:

- Improve environmental impact of the product

- Provide support during ecodesign studies on the product

- It is necessary to obtain some environmental certifications (EPD, Carbon Footprint…)

Compounding

The mechanical, physical and aesthetic properties of plastics can be adapted to any requirement

- Formulations of thermoplastic polymers with commercial and experimental fillers and additives

- Small batch compounding and sampling on pilot extrusion line

- Realization of charge-polymer pre-blends in dry blend

- formulation of thermosetting polymers

Technology scouting and material selection

Thanks to the cross-disciplinary expertise developed in different industries and the established network of contacts with manufacturers and material suppliers, we are able to support our customers in selecting the most appropriate materials for the final applications

- reinforced technopolymers for technical components

- Bioplastics as a replacement for traditional polymers

- packaging film

- slabs and panels for construction

- antistatic and conductive polymers

- fiber-reinforced composite slabs

- advanced labelling and decoration techniques

- advanced processing of thermoplastic composites

Technical and regulatory activities

We support companies in developing solutions and products that have regulatory as well as technical specificities

- Development of solutions and products for the pharmaceutical and biomedical sectors

- Development of innovative solutions for food and non-food packaging

- Conducting feasibility studies on the use of new polymers and additives that comply with specific regulations (food and drinking water contact, health safety, toy regulations...)